What Is Vertical or Radial Stiffness?

Vertical stiffness is how well a rim resists flexing and deforming vertically when a given load is applied. Typically, as the depth of a rim increases, the vertical stiffness is boosted. This rule applies to a rim made of any material.

Stiffer rims are more efficient since less power disperses as the wheels flex; however, shallower and typically less stiff rims are more comfortable to ride on, especially on rough surfaces for long hours.

Testing Goal

The rim is fixed vertically in the rig and increasing load is applied up to a preset limit. The amount of deformation is recorded automatically while the force is being applied. The aim of this vertical deformation test is to assess the behavior of carbon rims under a force pushing down from the weight of the rider and gear, and a force from the ground.

Test Standard

Deform at 50kgf

sample profile

| Size | Model | External Width | Depth | Load Max | Weight | Rim Condition |

| 700C | WR35 | 32mm | 35mm | 50kgf | 430g | New rim that has passed flatness and roundness tests |

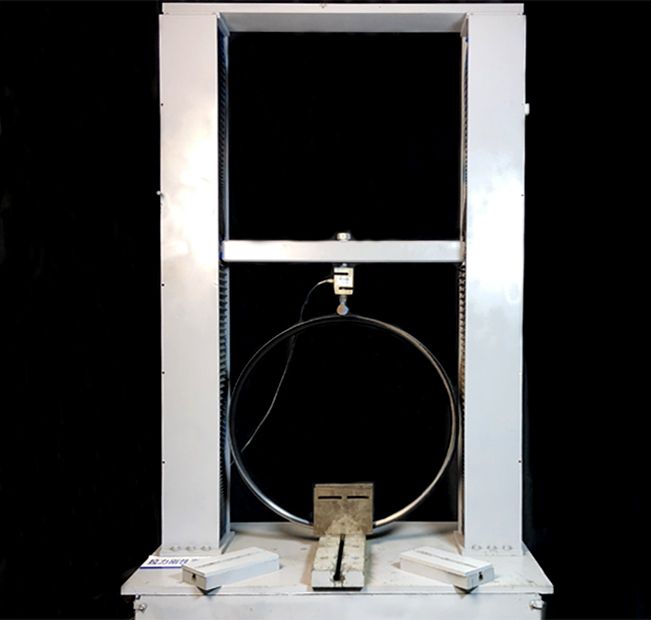

Test Facility

Vertical stiffness is tested on the Universal Testing Machine (UTM). The machine has a rigid base with a clamping device to hold the rim firmly. There is a compression fixture above the rim to apply increasing force, and all the rim deformation data is recorded automatically by the sensor above the compression cylinder. The sensor data is synced to the computer and results are displayed when the vertical stiffness test is finished.

Test Conditions

| Compression Item | Stainless steel cylinder |

|---|---|

| Moving Speed | 0.4mm/s |

| Moving Direction | Vertical |

| Test Positions | #1 Valve hole #2 Perpendicular to the valve hole |

| Controller | Remote Control |

Methodology

Step 1: Mark two test spots, not centrosymmetric to each other, on the rim;

Step 2: Clamp the rim rigidly on the rig;

Step 3: With the remote control, lower the compression item until it touches the edge of the rim at #1 test position;

Step 4: The compression fixture moves vertically at a controlled speed of .4mm/s to gradually increase the load to a given limit (50kgf in this test);

Step 5: Lift the compression fixture a bit and resume the touching-the-edge state;

Step 6: Rotate the rim to #2 test spot, and repeat the process;

Step 7: Export the two data charts from the computer.

test results

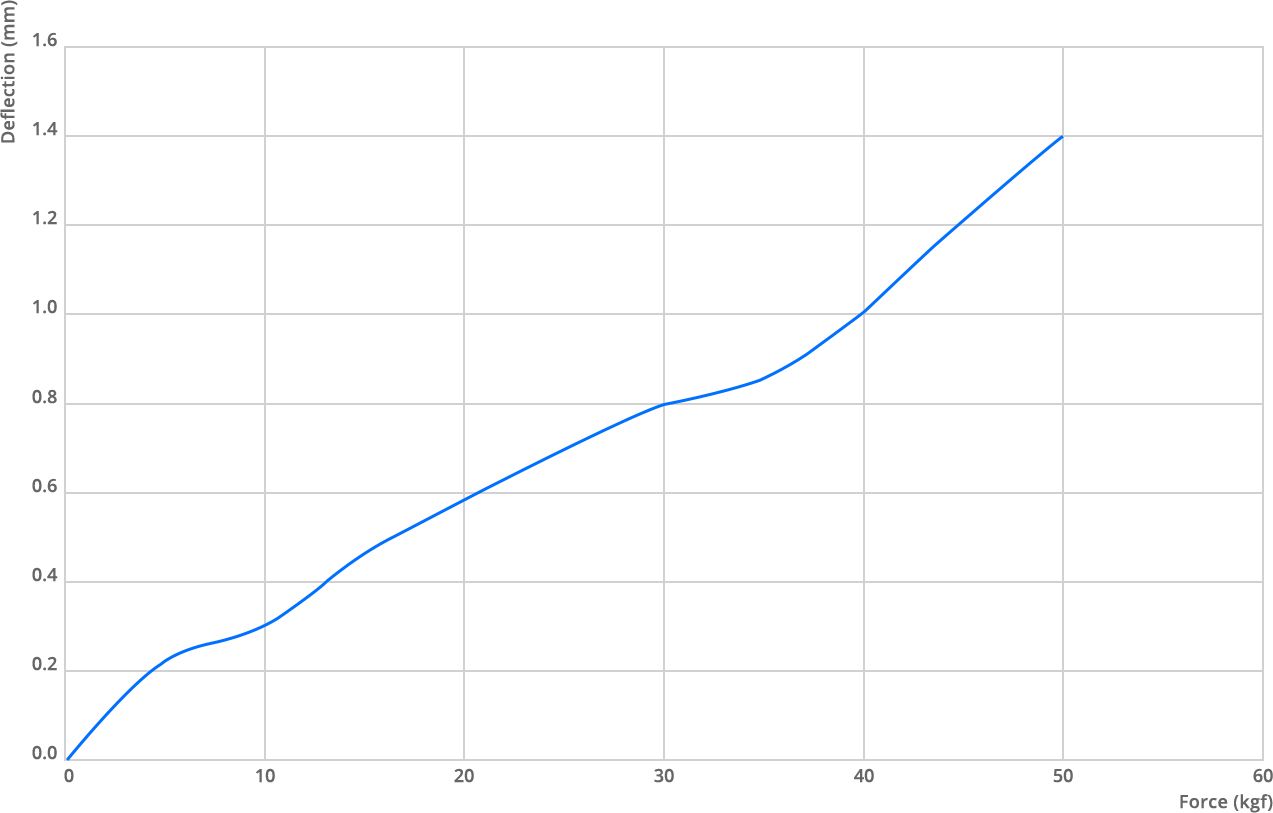

#1 Testing Position

| No. | Max Load | Max Deflection |

| 1 | 50kgf | 1.2mm |

#2 Testing Position

| No. | Max Load | Max Deflection |

| 2 | 50kgf | 1.41mm |

These results are valid only for the tested sample.

Conclusions

WR35 (25mm internal, 32mm external widths, 35mm depth) flexs vertically 1.2mm to 1.41mm under a load of 50kgf.

© All photos and test data by Light Bicycle

October 24th, 2020 | Light Bicycle

Get in touch

Feel free to leave a comment if you have any questions or suggestions on our products or other issues.

Please leave your name here.

E-mail is required for further contact.

Please enter a message.

We use cookies for a better experience. Learn more.

Your Cookie Preferences

We use cookies to improve your experience on this website. You may choose which types of cookies to allow and change your preferences at any time. Disabling cookies may impact your experience on this website. You can learn more by viewing our Cookie Policy.

-

Cookies required to enable basic website functionality.

-

Cookies used to understand how the website is being used.

-

Cookies that are used to enhance the functionality of the website.

-

Cookies used to deliver advertising that is more relevant to your interests.

Aceept All Cookies

Save Preferences

Reject All Cookies

Save Preferences

Reject All Cookies

Accept All Cookies